Motorcycle Dynamometer Tuning

The basics of dynamometer tuning, fuel mapping, and why you need to have it done to your motorcycle

Why you need a Fuel Map

In a fuel injected engine, and carbureted engines for that matter, fuel delivery is set up for the configuration of your engine. This means that the stock Electronic Control Unit (ECU), which controls when and how much fuel to deliver, via the fuel injectors, delivers fuel amounts based on the stock engine configuration as delivered from the factory.

An engineer developed this fuel delivery for the stock bore size, stock intake valves, stock head gasket, stock cam degree, stock crank, stock exhaust, stock exhaust baffles, stock air filter, stock air box, etc. Basically, the fuel delivery system in place is designed for a bike off the showroom floor. If any of these items are changed for better performance, sound, style, or for worse, engine wear, it will change the amount of air the engine can/will take in and push out. This change in air the engine pumps in and out will change the time and amount of fuel that is required. This relationship between air in fuel is referred to as an air fuel ratio (AFR)

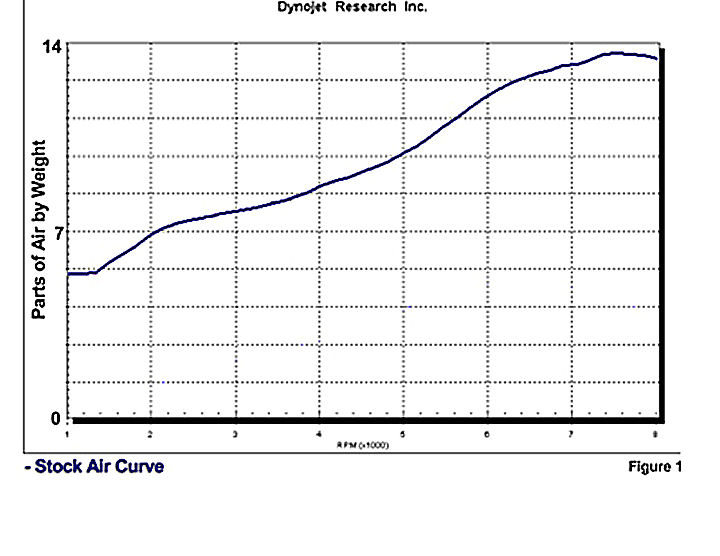

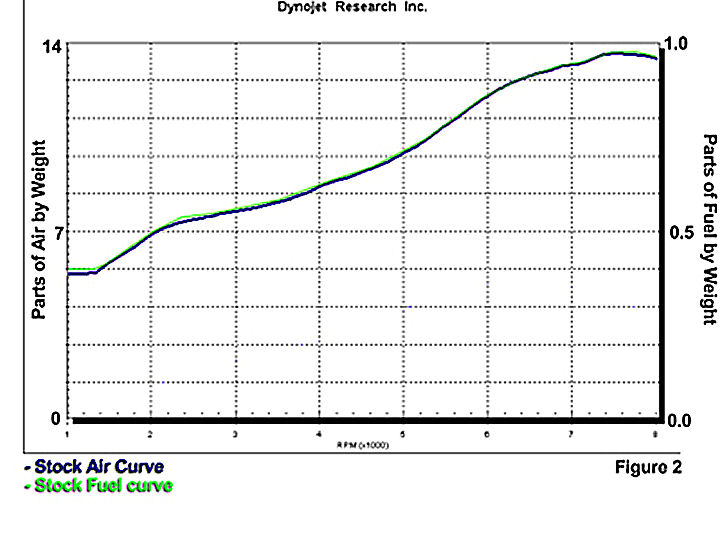

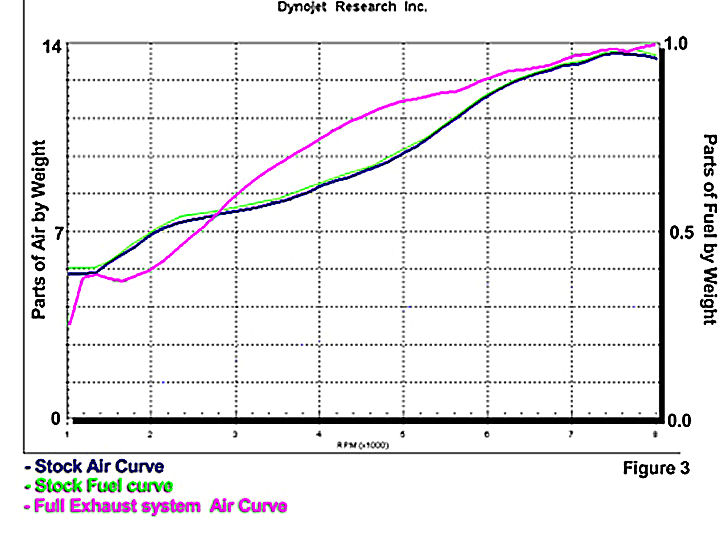

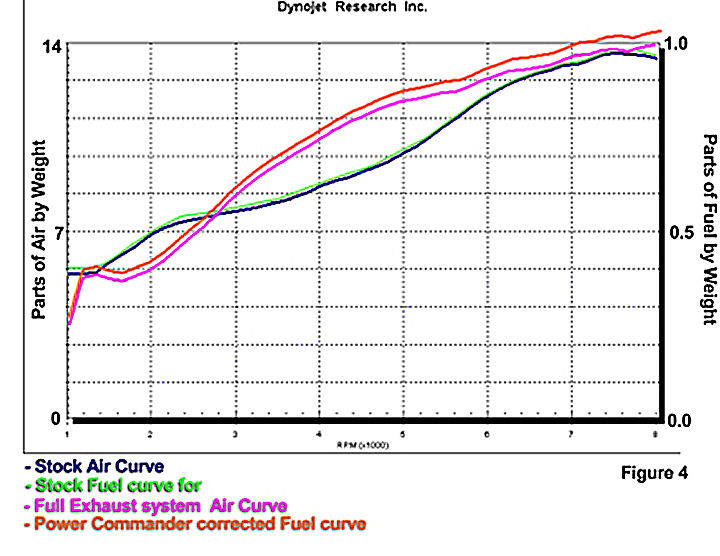

A great representation of this air flow change was created by Dynojet. They used it when explaining this concept to Power Commander Tuning centers. In the following graphs, you will see the air curve and fuel curve for a stock engine. Then on the third graph the air curve for full system exhaust. The fourth graph shows the change of fuel delivered, via a Power Commander, to match the new air curve. The Power Commander allows users to change the fuel delivery requirements without accessing the ECU. This new fuel delivery setup we call a fuel map. Just as conventional maps as used as a guide, a fuel map tells the ECU when and how much fuel to deliver based on engine load and rider inputs.

How to change fuel delivery

There are two main methods used to change fuel delivery on motorcycles. `

First is with a piggyback fuel management system. This is an electronic device that in installed between the ECU and the fuel injectors. Examples of piggyback systems are Dynojet Power Commanders, Bazzaz Z-FI, and Two Brothers Juice Box.

The second method we go straight to the source and directly modify the fuel map the engineer developed in the ECU. This is commonly referred to as ECU flashing or ECU tuning

Both methods accomplish the same goal, change fuel delivery to match the new air curve, achieving a desired air fuel ratio. There are some differences in how both these methods change fuel delivery and which one is better for your motorcycle will depend on your specific needs. Both methods have some of the same capabilities, but, there are unique features of both systems. If you need one of these unique features you may be limited to using one or the other. For instance, if you want to be able to run two fuel maps (a race fuel map, and pump fuel map) and switch on the fly (while riding); a piggyback system is usually better, easier to setup, and sometimes the only way to store two Fuel Maps.

Piggyback Systems

Piggyback fuel management systems change the fuel delivery by modifying the electronic signals that the ECU sends to your fuel injectors. This is where the term piggyback comes from, as it is piggybacking off the ECU to the injectors. Piggyback systems are great for adding some features that an OEM ECU does not have. Historically, piggyback systems have more resolution on their fuel maps (Resolution = amount data points where fuel delivery can be changed). Although, some late model ECU’s (Yamaha) have higher resolution.

Piggyback systems like a Power Commander can also dynamically adjust fuel delivery based on an added external sensors or control. For instance, a pressure sensor, commonly used on boosted engines, can be configured to add fuel based on the amount of manifold pressure. For example, a specific fuel map can be made when a nitrous system is engaged to compensate for the change in air delivery. Bazzaz’s management system can add traction control(TC) to a bike that didn’t come with a TC system. Piggyback systems are live tuning friendly as well. This means that when tuning on a dyno fuel changes can be made in real time, while the bike is running, and changes take effect immediately.

ECU Mapping

ECU fuel tuning takes place by changing the fuel maps directly in the stock ECU. The fuel map resolution is typically smaller than that of a piggyback system. Changes to an ECU cannot be made in real time while the bike is running on dyno. Changes must be written to the ECU, in a processing called flashing. An exception to this are factory Race ECUs, which do support live tuning similar to piggyback systems. When tuning directly through the ECU, the motorcycles ignition switch has to be turn OFF and then back ON to finalize the updated settings. Also, the process of writing changes to the ECU, known as flashing, can take up to 5 minutes. While directly changing fuel maps in the ECU has the same effect as piggyback systems, access to the ECU allows control or changes to more than just fuel delivery. We can change ignition timing maps, STP (secondary throttle plates) maps, RAM air affect, radiator fan on/off temperature, RPM limits, dwell times, velocity stack switchover, etc. However, these other modifications vary by ECU. Access to the ECU allows us to change other things besides just the tune of the bike. This includes features commonly used in racing such as a quick shifter, Pit Road Limiter, and Launch Control. There are also features that are helpful in both racing and street riding applications. For example, we can disable or turn off the exhaust servo motor, AIV valve, O2 sensors, fuel cuts, top speed restrictions, and ignition retarding.

In both methods fuel delivery is changed in “maps” that reference a set point in the engine, mostly a throttle position vs. RPM table. Although, some applications use manifold pressure vs. RPM, TPS change vs. MAP sensor correlation maps, and even delta TP influences fuel delivery. These tables contain the data points where we make changes. In a TP vs. RPM table data points can be every 10% throttle and 500rpm, while others will have the TP’s where riders spend most of their time and less where they don’t. (2,5,10,15,20,25,30,40, 60,80,100%). Tables can use rpm increments of every 250rpm up to 500.

Once we have map table defined the rest is done on the dyno. The process is relatively simple, but can take up to 6 hours to complete. We run the bike at a certain throttle position, say 20%, record the air fuel ratio from the exhaust system as the bike is running, then adjust the fuel delivery to produce an air fuel ratio that works well for that given throttle position and rpm. In general, we are looking for an air to fuel ratio of 13.0 to 13.4. This is the best overall range for most engines. There are some throttle positions and RPM data points that like different air fuel ratios. Knowing and finding these air fuels at different data points are found based on dyno testing and rider feedback.

Properly prepared motorcycle

Now that you understand why you need your motorcycle mapped, as well as what we are doing while we are mapping it, let’s look at things to consider before you bring your motorcycle in for fuel mapping.

Fuel mapping should be done as the last step in a motorcycle build, or a change to the engines configuration. If you have your engine built, bore size changed, cams installed, performance exhaust installed, aftermarket air filter installed, you probably need your fuel delivery checked and/or changed. If any of these items are not installed properly or another item is not in good condition when the bike is mapped you will have a map built for an improperly operating motorcycle. Also, an engine is a wearable item and parts wear over time. Everything, including the existing parts you did not change when you added your performance exhaust, must be in proper working condition. Many times, we have had a bike in for mapping only to find that the fuel pressure is weak at high RPM. While we can change the delivery and essentially map the bike to the correct air fuel ratio over the entire TP and RPM range it is not correct. This is because when the fuel pump finally fails and a new one is installed, the air fuel that was set on a weak pump is now to rich with a good working pump, and you will have to remap your bike.

Lastly, we do adjust fuel maps half season for racers because an engine will wear. When the engine wears we are trying to maximize smooth throttle and power output across the throttle position and RPM range and improvements can be made. Remember when you rebuild your engine to the same spec the original map was built on. It will still deliver the proper air to fuel ratio.

For the best tuning performance out of your motorcycle ECU Tuning and/or a Flash, should be combined with Fuel Map tuning.

Before your bike arrives for tuning, make sure the following has been addressed for a good quality fuel map –

1. Maintenance is up to date –

a. Valve lash in proper adjustment, tight valves can cause low compression poor mapping condition.

b. Air filter is clean, if we build a map on a dirty air filter, when you clean it, your engine will flow more air and your map will be off, probably too lean.

c. Fresh engine oil - we will be running your engine through every throttle position and rpm available you’ll want all your oils anti wear additives working in full force for this 3+ hour engine strain.

d. Spark plugs, they should be in good condition. NGK manufacture recommended.

2. Have a good exhaust system – If you worried about making power or want a dyno number to show your buddies, don’t bring us a bike with a welded-on tip or a half system from a back-yard mechanic. While it may sound good to you, an exhaust engineer did not maximize the header lengths and collection joints for the proper negative pressure waves for engine scavenging. These exhaust systems will not give you the best power curve, and in many instances, can even cause the bike to lose power versus a stock exhaust system. Spend the money for a quality exhaust system. We recommend M4, Akrapovic, Yoshimura, Leo Vince, Graves, and Vance & Hines, to name a few. Always pick a full system or catalytic converter removal system (sometimes referred to as a Y pipe or ¾ system) if available.

3. Fuel management installed properly – If you or your buddy installed your fuel management system with a couple beers at midnight, there is a good chance a mistake was made. Just because a bike still runs after a piggyback system was installed does not mean that it was installed correctly. A properly installed and calibrated throttle position sensor must be checked before we start mapping. If it’s not done correctly, expect us to correct the issue for a nominal charge.

4. Flashing before fuel mapping – If you read our ECU tuning section, you’ve learned that the ECU changes will affect fuel mapping requirements with a piggyback system. If you do an ECU Flash after a fuel map, you may need to re-map your bike. Flashing should be done before a final fuel map.

5. Air Injection Valve (AIV) block off plates – We are changing your fuel delivery based on the Air/Fuel Ratio(AFR) coming out of your exhaust. The AIV system needs to be disabled before fuel mapping. You can purchase block off plates for some models and install them, or have us do it. If block off plates are not used we will have to disable the AIV system before mapping.

6. Good fuel pressure – One of the biggest issues we see with late model motorcycles and ethanol fuel. Fuel pressure can be high enough for a bike to run throughout most of TP and RPM Range, but it will be weak in certain areas, mostly high TP and RPM causing a weak bike. Customers normally think it’s mapping and bring a bike in for that. Here’s where the serious issue arises. If we map on a low-pressure fuel pump. The bike will run better after the map and have a correct AFR, but when the pump finally quits and you replace it with a new one, the map will be off. The higher pressure of a new fuel pump will cause the map that was built on a weak one to now be too rich. Back to the dyno again and you will need to pay for a new fuel map. There are some tell-tell signs of this, mostly high mileage bikes or bikes that have been sitting, but don’t be surprised when we check the fuel pressure before we begin mapping, the minimal extra charge will help you in the long run and is cheaper than buying two custom maps.

7. Chain/sprockets – make sure they are in good condition. A worn-out chain will cause inaccuracy in dyno readings, mainly shorter gearing reads less power. it’s not that your bike makes less power it’s just the dyno calculation to stabilize difference in gear ratio’s produces lower outputs for shorter gearing.

These are the basic issues that we run across the most. If you have any other questions don’t hesitate to call/email and ask. We are here to give you the best product and looking out for your best interest.